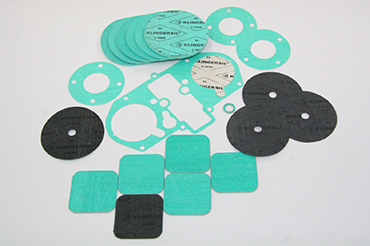

Non-Asbestos Gaskets

Compressed Non-Asbestos Gaskets (CNAF) Materials are used in high pressure and high temperature applications. Rama industrial Products Corporationis a leading supplier and manufacturer of different classes such as the Non-Asbestos Full Face & Ring Gaskets with different pressure capacities. The different application types such as piping systems use the Non Asbestos Jointing Sheets for maximum integrity. They are easy to remove from the flange assembly after use due to the anti-stick coating properties, are very economical and will withstand a temperature range from -196°C up to 450°C (grade may vary dependent upon the application) and suit- able for pressures up to 140 bar (again depending upon the grade).

CNAF Gaskets

Compressed Non Asbestos Synthetic Fibers gasketing materials (CSF), OrganicFi- bres, Aramid Fibers, Glass Fibers, Carbon Fibers, Mineral Fibers, etc.,

Available with additional improvements: Graphite coating, PTFE & Anti stick coating, With wire reinforcement on request.

Features

- Excellent chemical resistance.

- Wide temperature range

- Excellent resistance to stress

- High levels of joint stability.

- Outstanding sealing integrity

- Long lifespan.

Application

Common Industries Utilising Non-Asbestos Fibre

- Oil and Gas

- Chemical Processing

- Petrochemical Industry

- Process Industry

As a general rule, Novus

- Is good for use with water and petrol

- Has good impermeability to gas

- Exhibits good recovery

- Material Handling

- HVAC

NBR Gasket Material Benefits

- High pressure & heat resistance

- Top sealing power

- Excellent torque retention

- Oil resistant (petroleum, mineral & vegetable oil)

As a general rule, Klinger®

- Exhibits good recovery

- Has excellent bolt stress retention properties

- Has excellent sealing performance

- Is easy to remove

- Is easy to handle/install

- Has good impermeability to gas

Size And Construction

The non-metallic gaskets are produced in several sizes and shapes for meet the most demanding applications. They are available in standard and non-standard gasket design. For non-standard gaskets we can provide any shape and size ac- cording to customer design or sample.

Cutting Capabilities

With our cutting technology, experience and knowledge we are able to cut almost any material. A wide range of cutting euipment provides competitive pricing and high quality regardless of the gasket size or quality. A large range of presses, special cutting tools, CAD-CAM CNC,Water jet cutting and also a skilled team for the.

Dimensions of standard Sheet

sheet size(mm): 1000 x1500 , 1500 x 1500, 3000 x 1500, 4500 x 1500

Thickness(mm): 0.5 , 0.8, 1.0, 1.5, 2.0, 3.0, 4.0, 5.0

Other dimensions and thickness on request.

Gasket Materials and Application

| Composition | Max T (C/F) | Max P (bar/ psi) | Properties & application | |

|---|---|---|---|---|

| Organic Fibres, NBR | Peak Continuous | 180/356 140/284 | 40/580 | Good resistance to water, gases, oils,fuels at lower loading |

| Aramid fibers, NBR | Peak Continuous | 1250/482 200/392 | 50/725 | Good resistance to water, gases, oils, fuels at medium loading |

| Aramid fibers, NBR | Peak Continuous | 280/536 220/428 | 80/1160 | Good resistance to water, gases, fuels, food industry and oils good dynamic resistance for higher loading. WRAS/WQC, approved |

| Synthetic fibers, NBR | Peak Continuous | 350/662 270/518 | 100/1450 | excellent and economical solution for a wide range of applications |

| Aramid fibers, NBR | Peak Continuous | 280/536 250/482 | 100/1450 | Excellent gasket material for general use with extremely wide application range.- WRAS/WQC. |

| Glass fibers, NBR | Peak Continuous | 440/824 350/662 | 100/1450 | Sealing of very broad range of media at high temperatures. |

| Carbon fibers, NBR | Peak Continuous | 400/752 300/572 | 100/1450 | Sealing of steam and very aggressive media in chemical and petrochemical industries |

| Aramid fibers, NBR | Peak Continuous | 280/536 220/428 | 80/1160 | Sealing at low surface stresses in automotive and chemical industry |

| Aramid fibers, CR | Peak Continuous | 350/662 270/518 | 100/1450 | Sealing of different applications in the refrigeration industry automotive and chemical industry |

| Aramid fibers, CSM | Peak Continuous | 200/392 150/302 | 60/870 | Sealing of extremely aggressive media in many industries |

| Aramid fibers, NPR, Wire reinforced | Peak Continuous | 400/752 350/662 | 140/2030 | Applications where resistance to the high dynamic loadings is the premium requirement |

| Inorganic, NBR, wire reinforcement Wire reinforced | Peak Continuous | 550/1022 450/842 | 500/7251 | Extreme dynamic conditions in the automotive industry, petrochemical industryand shipyards |

| Inorganic fibers, NBR, special reinforcement | Peak Continuous | 650/1202 600/1112 | 500/7251 | The most demanding requirements in automotive industry, petrochemical industry & shipyards |