Spiral Wound Gaskets

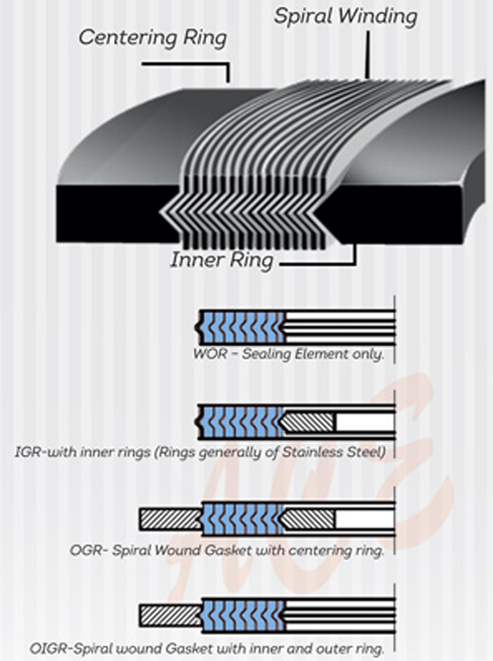

Spiral Wound Gaskets are special semi-metallic gaskets of great resilience; there- fore they are very suitable for applications featuring heavy operating conditions. SWG manufactured by spirally winding a V-shaped metal strip and a strip of non-metallic filler material. The metal strip holds the filler, providing the gasket with mechanical resistance and resilience. SWG can be reinforced by an outer centering ring and/or inner retaining ring. The outer centering ring controls the compression and holds the caf gaskets centrally within the bolt circle. The inner retain-ing ring increases the axial rigidity and resilience of the cnaf gaskets and acts as a Heat and Corrosion barrier eliminating turbulence between the gasket Inner diameter and the flange bore so avoiding erosion of the flange faces

Spiral Wound Gaskets Standard Styles

| WOR | Spiral Wound Metaillic Gasket- sealing element only – without guide and Inner ring |

| IGR | Spiral Wound Metallic Gasket with inner ring (Inner rings generally of stainless steel) |

| OIGR | Spiral Wound Metallic Gasket with Guide (outer) ring. (Centering ring made of carbon steel ,stainless steel and other metals) |

| OGR | Spiral Wound Metallic Gasket with inner & outer rings. (Rings are made of carbon steel stainless steel and other metals) |

- Temperature range of -200°C to in excess of 550°C

- Pressures up to 300 bar

Spiral wound gaskets are used in Refinery, Petrochemical, Chemical, Steam lines and Process Industries, where they have many advantages over older types of gaskets.

Flange Standards

FLANGE STANDARDS SOR, SIO, SIOH, SIR type spiral wound gaskets can be manu- factured in accordance with all relevant gasket standards and specifications to suit the following

ASME/ANSIB16.5 – MSS SP44 (ASME B16.47 SERIES A) (AWWA)

BS 1560, BS10, BS4504 – DIN FLANGES, JIS FLANGES

API 605 (ASME B16.47 SERIES B) – FRENCH NF STANDARD

Common Fillers Used

Fillers Materials

- Graphite Mica 350 F (Temperature)

- Graphite 99.8% purity 1200 C

- Non asbestos 550 C

- PTFE

- Ceramic

- 350 F (Temperature)

- 1200 C

- 550 C

- 250 C

- 1000 C

Winding Material

- SS304

- SS316

- SS347

- SS321

- Monal400

- Nickel 200

- Titanium

- Iconel 600

- Inconel 625

- Incoloy825

- 650 Deg C

- 800 Deg C

- 870 Deg C

- 870 Deg C

- 800 Deg C

- 600 Deg C

- 540 Deg C

- 1000 Deg C

- 1000 Deg C

- 1000 Deg C

Inner And Outer Ring

Carbon Steel, Stainless Steel 304,304L, 316,316L,31 611,321,347, MONEL® 400,In- conel® 600,625,800, Incoloy® 800, 825, Nickel 200, Titanium, Hastelloy, Copper

Spiral Wound Gasket Sizes

Size & Shape as per Prevailing International standards or Customer needs can be produced.

Gasket Compression & Choice of Thickness

Nom. Thickness

- 2.5 mm(.098 in)

- 3.2 mm(.125 in)

- 4.5 mm(.175 in)

- 6.4 mm(.250 in)

- 7.3 mm(.285 in)

Compressed Thickness

- 1.9/2.1mm(.075/.085 in)

- 2.4/2.6mm(.095/.105 in)

- 3.2/3.45mm(.125/.135 in)

- 4.6/4.8mm(.180/.190 in)

- 4.7/4.9mm(.185/.195 in)